In today’s demanding industrial environment, manufacturers face constant pressure to maximize uptime while minimizing operational costs. The frequent maintenance requirements of traditional magnetron systems create a familiar cycle of frustration: unexpected downtime, costly tube replacements every few thousand hours, inconsistent power output, and the constant challenge of maintaining precise process control. For many operations, these issues directly impact bottom-line results and production reliability. Understanding the difference between solid-state vs magnetron systems is critical for manufacturers choosing a heating system.

As the first North American manufacturer of high-power solid-state microwave energy generators and systems, Crescend Technologies brings over four decades of RF expertise to this challenge. Since pioneering the world’s first 50-kilowatt solid-state microwave generator in 2019, we’ve shipped over a million watts of microwave power worldwide, transforming industrial processes across multiple sectors. Our deep understanding of both traditional magnetron systems and cutting-edge solid-state technology puts us in a unique position to guide manufacturers through this technological evolution.

In this article, we’ll explore the fundamental differences between solid-state and magnetron microwave technologies, helping you understand how these differences impact your operations. You’ll learn about the specific advantages of solid-state systems in terms of reliability, efficiency, and process control, and discover how this technology can reduce your total cost of ownership while improving product quality.

Whether you’re considering an upgrade to your existing system or planning a new installation, this article will provide you with the insights needed to make an informed decision about the future of your microwave processing capabilities.

Solid-State vs. Magnetron Systems: Consistent Performance Throughout Lifespan

One of the most compelling advantages of solid-state generators lies in their remarkable stability over time. Traditional magnetron systems follow a predictable but problematic pattern of degradation, where power output and performance gradually decline until eventual failure. This degradation not only affects product quality but also requires frequent monitoring and adjustment of process parameters to maintain consistent results.

In contrast, solid-state generators maintain their power output and performance characteristics throughout their operational life with remarkable consistency. This stability eliminates the need for constant process adjustments and ensures that the energy delivered to your product remains constant from day one through years of operation. The practical implications of this consistency are far-reaching: production schedules become more reliable, product quality remains uniform, and operational planning becomes more straightforward.

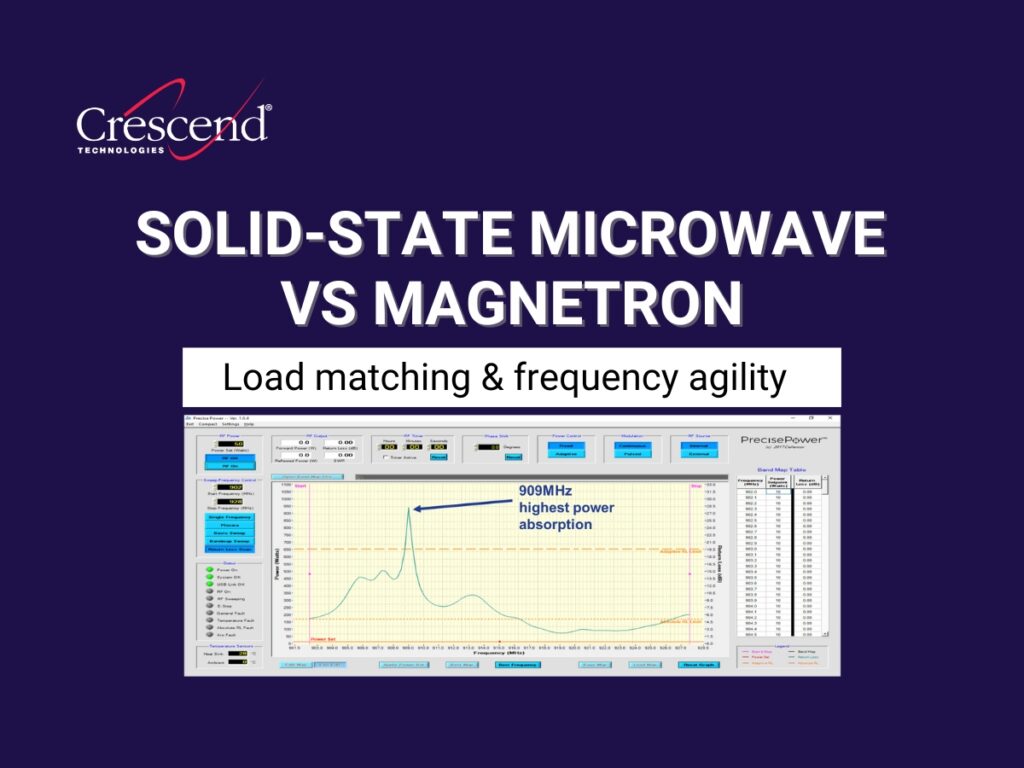

Advanced Load Matching Capabilities

The frequency agility of solid-state vs magnetron systems technology represents a revolutionary advancement in microwave processing efficiency. Our systems can precisely identify and operate at optimal frequencies for specific materials and processes, something traditional magnetron systems simply cannot achieve. Through sophisticated frequency sweeping and real-time adjustment capabilities, our solid-state generators can pinpoint exact frequencies within the 902 – 928 MHz band where power transfer to the material is maximized. For example, 909 MHz is possible.

This precision in frequency control translates directly to process efficiency. When a system operates at the optimal frequency for a given material, energy transfer becomes more efficient, heating becomes more uniform, and overall process time can be reduced. The ability to fine-tune the operating frequency also means that the same system can be optimized for different products or materials simply through software adjustments, providing unprecedented flexibility in production environments.

Adaptive Processing for Changing Conditions

Perhaps one of the most sophisticated capabilities of solid-state technology is its ability to adapt to changing material properties during processing. In real-world applications, materials often undergo significant changes in their dielectric properties as they heat up or transform. Our solid-state systems can detect these changes and automatically adjust their operating parameters to maintain optimal energy transfer throughout the entire process cycle.

Consider a typical heating application where a material’s optimal absorption frequency shifts as its temperature increases. A traditional magnetron system, locked to a single frequency, would continue operating at its fixed frequency, becoming increasingly inefficient as the material properties change. Our solid-state generators, however, can track these changes and adjust their output frequency in real-time, maintaining peak efficiency throughout the entire heating cycle. This adaptive capability not only improves energy efficiency but also ensures more uniform and controlled processing results.

Precision Power Control and Rapid Response

The level of control offered by Crescend’s patented PrecisePower™ software with it’s solid-state technology sets a new standard in industrial microwave processing. Unlike magnetron systems, which typically require several seconds to adjust power levels, our solid-state generators can modify their output power almost instantaneously. This rapid response capability enables:

- Prevention of thermal runaway conditions through immediate power reduction

- Precise temperature control within tight tolerances

- Sophisticated power modulation schemes for sensitive materials

- Consistent product quality through exact power delivery

The ability to precisely control power is a key differentiator between solid-state vs magnetron systems.

Innovative Pulse Mode Operations

Our solid-state systems introduce advanced pulse mode capabilities that open new possibilities for process optimization. While traditional systems are limited in their ability to modulate power, our technology enables precise control over duty cycles and pulse patterns. This capability proves particularly valuable in plasma applications, where maintaining optimal conditions often requires sophisticated power delivery patterns.

For process developers, this feature provides an entirely new dimension of control. By experimenting with different pulse patterns and duty cycles, operators can often achieve the same process results while consuming significantly less energy. In some cases, pulsed operation has been shown to improve product quality while reducing overall energy consumption by 25% or more.

Infrastructure and Installation Benefits

The architectural advantages of solid-state systems extend beyond the generator itself to impact entire facility designs. Traditional magnetron installations often require extensive waveguide networks to distribute power from a central source to multiple application points. Our solid-state approach enables a fundamentally different strategy:

- Distributed power generation with right-sized units at each application point

- Reduced transmission losses through shorter waveguide runs

- More flexible installation options

- Simpler maintenance access and system modifications

Lifecycle Economics and Operational Benefits

The economic advantages of solid-state vs magnetron systems become particularly compelling when viewed through the lens of total cost of ownership. While traditional magnetron systems require tube replacements every few thousand hours – often as frequently as every two to three months in demanding applications – our solid-state generators are designed for 10-20 years of continuous operation. This longevity fundamentally changes the maintenance equation:

- Elimination of periodic magnetron replacement costs

- Reduced maintenance labor requirements

- Minimized unplanned downtime

- Lower inventory carrying costs for replacement parts

- Increased production reliability and throughput

Process Control and Analytics

Modern manufacturing demands data-driven decision making, and our solid-state systems deliver unprecedented visibility into process parameters. The sophisticated control software accompanying our generators provides real-time monitoring and analysis capabilities that transform what was once considered a “dark art” into a precise, controllable science.

Operators can monitor and adjust key parameters in real-time, while process engineers can analyze historical data to optimize performance and energy efficiency. This visibility enables:

- Faster process development and optimization

- More consistent product quality

- Improved troubleshooting capabilities

- Data-driven decision making for process improvements

Conclusion

The transition to solid-state microwave technology represents more than just an upgrade in power generation – it’s a fundamental shift in how industrial processes can be optimized and controlled. While the initial investment in solid-state technology may be higher than traditional magnetron systems, the combination of improved performance, reduced maintenance requirements, and enhanced process control capabilities delivers compelling value over the system’s lifetime.

For companies looking to enhance their processes, reduce operational costs, and improve product quality, solid-state microwave technology offers a comprehensive solution that addresses many of the limitations inherent in traditional magnetron systems. As the technology continues to evolve and improve, early adopters are already realizing significant competitive advantages through improved efficiency, reliability, and process control.

Other information you may find helpful: Solid-state vs Magnetron interview with Adam Jones, PE.