Applicator Design

In addition to being leaders in the design of cutting-edge microwave technology, Crescend is proud to offer microwave applicator design consulting. This includes the design of custom microwave heating applicators such as furnaces or resonant cavities, waveguide mode transitions, optimized antenna design/selection, and application feasibility studies. This is accomplished through the use of 3D CAD modelling and powerful electromagnetic wave simulation software.

Starting Point

The design process begins with the need to answer questions regarding the fundamental characteristics of a potential microwave applicator. Factors such as desired mass throughput, operating frequency, vacuum-sealed or gas-purged cavities, plasma generation application, and the load material’s dielectric and thermal properties affect various design parameters such as recommended operating frequency, applicator size, antenna feed type, appropriate power level, and whether the system will be conveyor based, batch-style, or continuous-flow. This all informs the basic size and shape of the microwave applicator, as well as the approximate location of the antenna feed. The load material’s physical properties and phase state, and desired output material, will also play a large role in determining the applicator geometry and type.

Simulation

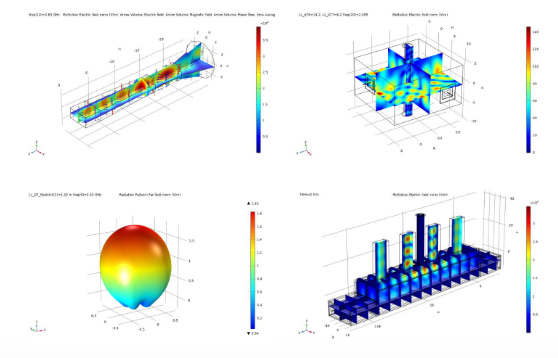

Once the basic design aspects of the applicator like cavity size and antenna feed have been determined, and the relevant material properties identified, an RF heating simulation can be constructed using COMSOL Multiphysics. This simulation can be used to determine where electromagnetic hot/cold spots exist in a cavity and in the load material, estimate the temperature rise of the load, calculate the amount of power reflected back to the input port and the amount absorbed by the load, and identify and areas of microwave leakage in a cavity design. This feedback can then be used to adjust and optimize the cavity geometry in order to concentrate microwave energy at a desired location, determine the optimal location of the load material inside a cavity or applicator, compare the performance of different antennas for a specific heating application, and mitigate and leakage of microwave energy.

Mechanical Drawing

Once the electromagnetic design of a microwave cavity or heating applicator is completed, a complete mechanical design of the system is required. This may consist of integration into an existing production line or the development of a stand-alone microwave system. The use of heating simulations eliminates the need for costly prototypes and significantly reduces the time to reach production. Some example applications are shown to the right: