Thermal Processing Gets a Solid-State Upgrade

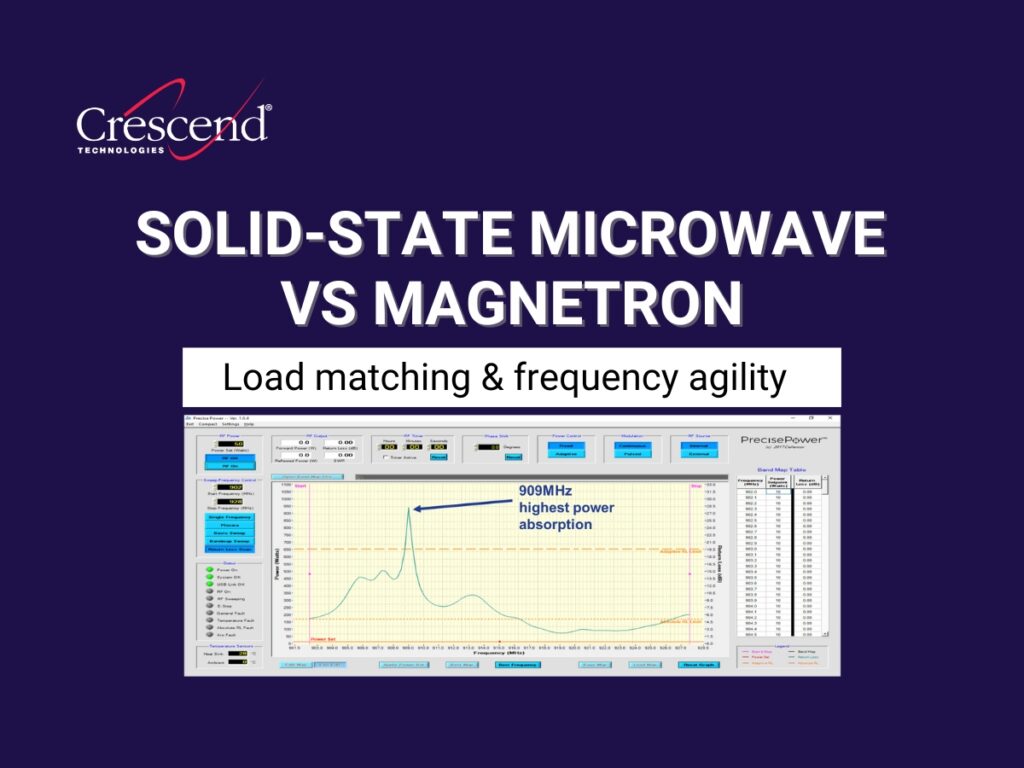

As seen in Industry Today. Improve energy efficiency, reduce downtime, and scale production with solid-state microwave technology for thermal processing. Industrial heating powers a wide range of processes from drying powders and curing coatings to complex thermal reactions in food, chemical, and specialty material manufacturing. Yet many of the conventional systems still in use, like […]

Thermal Processing Gets a Solid-State Upgrade Read More »