Simulation & Modeling

Simulation & Modeling

Crescend uses COMSOL Multiphysics® to perform electromagnetic simulations of microwave cavities, applicators, and antennas. COMSOL Multiphysics® is a powerful finite element multiphysics simulation software suite that can be used to model and simulate various microwave heating applications. Sometimes we receive basic questions that are specific to a customer’s application, and COMSOL® allows us the flexibility of testing new ideas without many of the negatives of testing it via trial-and-error.

Real World Example

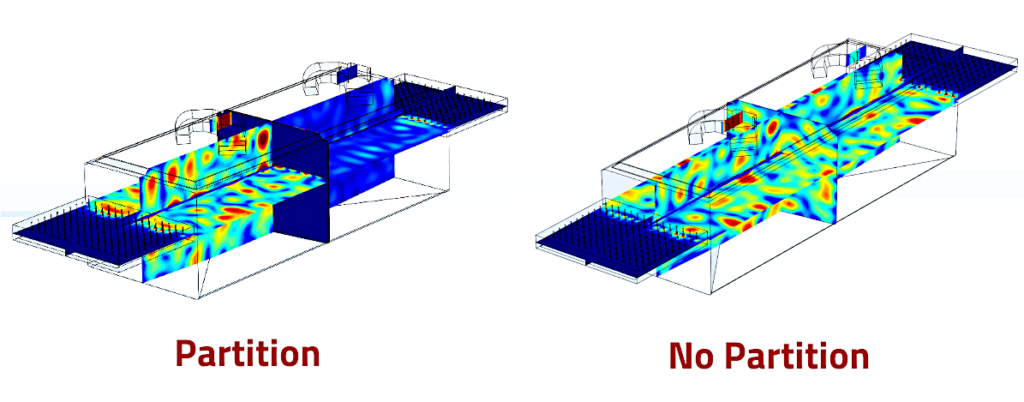

Crescend has a customer with a system in place, that determined that their product quality improved dramatically when it was exposed to a large amounts of microwave energy in the beginning of their process, and then finished with much lower power. One low cost way this could be achieved was to add a metal wall or partition inside of their oven as opposed to adding a new cavity in series with the existing oven.

We turned to computer simulation to validate whether this method could work as expected to solve their problem, and quantify the power attenuation that would result from including a partition inside the center of the microwave oven. The picture below shows how effective modeling can be at validating an idea before any metal was cut or welds were made, saving time and money and most importantly, solving the customers problem.

COMSOL Multiphysics Modeling and Hot spots

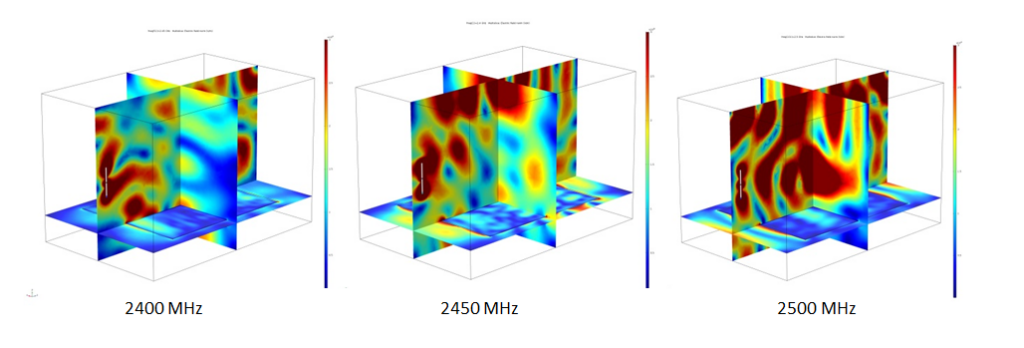

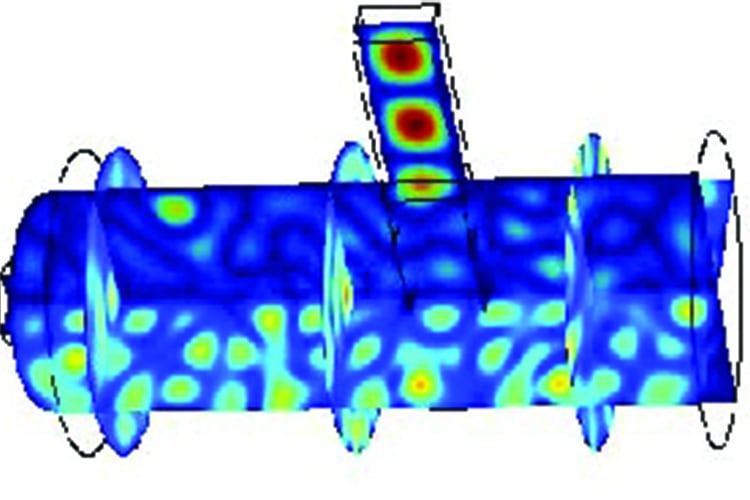

Another application for computer modeling has been designing custom multi-mode cavities that distribute energy evenly to help alleviate hot and cold spots in the energy fields. Below is a picture of how the energy density changes with microwave frequency. The video below shows real-world testing that validates the models predictions.

We turned to computer simulation to validate whether this method could work as expected to solve their problem, and quantify the power attenuation that would result from including a partition inside the center of the microwave oven. The picture below shows how effective modeling can be at validating an idea before any metal was cut or welds were made, saving time and money and most importantly, solving the customers problem.