Industrial Materials Drying

Industrial Materials Drying

Many industrial materials go through many steps before becoming a finished product. These steps often include water or other solvents. Removing these solvents is usually an important step. Microwaves can selectively and rapidly heat these polar solvents to produce fast drying rates.

Microwave heating is fundamentally different and superior to conventional drying methods such as convection heating. It is fast, efficient, and precisely controllable. Microwave systems are used to dry a wide variety of materials including various chemical powders, lithium battery electrolytes, agricultural and food products, biomass, plastics, minerals, ceramics, wood materials, fibers and papers, filter materials, sand casting molds, and much more. Microwave systems cover a wide range of process rates up to hundreds of tons per day.

Crescend’s microwave heating technology offers fast, selective, and precisely controlled drying, making it superior to conventional methods. With the integration of our Precise Power™ Software, you gain even greater control and flexibility, optimizing your industrial heating processes with unmatched precision.

Fast Volumetric Heating

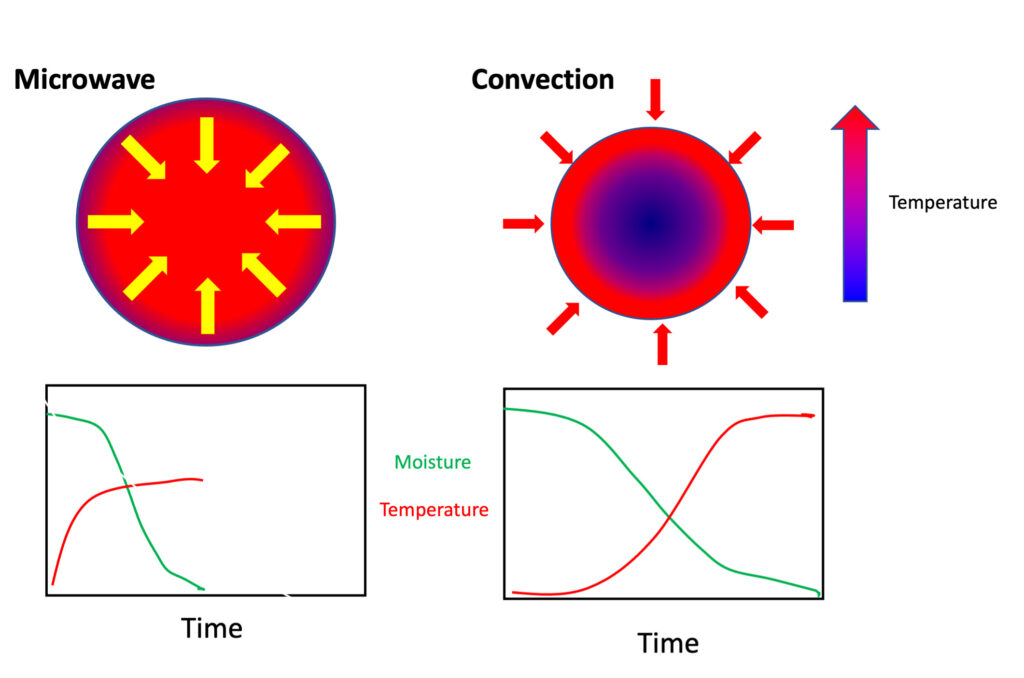

Microwaves penetrate deeply into the material and heat it uniformly. Other methods such as convection heat the surface of the material and must conduct to the interior. This takes time and creates a temperature gradient where the outside temperature is much higher during most of the drying period. This has a profound effect on the drying curve and is the reason why microwave heating is almost always significantly faster than other methods.

Precisely Controlled, Low Temperature Drying

Water molecules are highly reactive to microwaves, much more so than most other materials. Radio waves cause strong vibration of water molecules which results in frictional heating, which in turn vaporizes the water. Other substances in the material usually do react as much, so water is selectively heated. One highly beneficial result of this phenomena is that the drying occurs at a low temperature, so the overall material temperature does not get hotter than the boiling point of water. Typical temperatures are about 80 to 90 degrees centigrade. As many materials are temperature sensitive, microwave drying often produces a higher quality product than other drying methods.

Most microwave applicators are equipped with sensors that measure the temperature of the material while it is being heated. IR pyrometers or thermal images are commonly used for this purpose. The sensor data provides feedback to the microwave’s control computer. Thanks to the fast power control response time of Crescend solid state generators, the drying temperature can be precisely controlled, typically within one degree.

Conveyor belt ovens and horizontal paddle mixers are most often used in drying applications.